Description

Technical Specifications

SPECS V Port Ball Valve belongs to a fixed Ball Valve and is a kind of adjusting and cutting-off valve with a v-shaped notch in the ball. The character of the partial spherical surface of the valve plate and V shaped cut increases the adjustable ratio, with shear function suitable for paper making and other industries. It is widely used in petroleum, chemical industry, paper making, metallurgy, water treatment and other industrial sectors.

Applicable Standard

Design & Manufacture Standard: IEC60534

Face to Face: ISA S75.04, IEC/DIN 534-3-2 (Flange), Factory Standard (Wafer)

End Connection: ASME B16.5, EN1092-1

Test Standard: IEC60534-4

Products Range

Size: 1/2"~24"

Pressure Rating: ASME CLASS 150~300

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: RF

Operation: Operation: Manual, Gear, Pneumatic, Electric

Design Features:

Body

Single-piece body prevents leaks caused by separate flanges or locking rings.

V-port Segment Ball

Specially designed V-notch ball provides

strong cutting stress and tight sealing.

Well ground notched ball surface ensures

small operating torque and tight seal,

especially for metal seated segment valve.

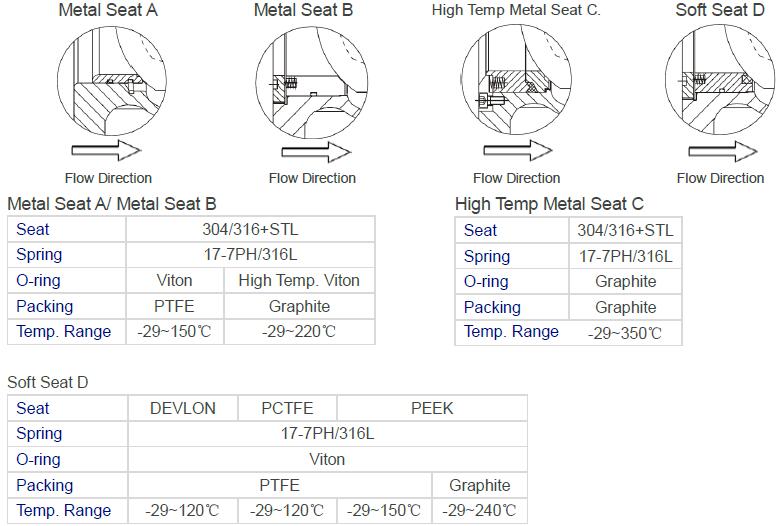

Seat

Special seat design eliminates cavity

between seat and valve body. This,

consequently, prevents media from jamming

between seat and body, ensure reliable

sealing.

Seal Surface

Nitriding/Tungsten Carbide/Satellite

Alloy/Nickle Base Alloy plating are available for

abrasive media.

Stem

Stem is finely grounded to match actuator

excellently, which prevents rocking motion

and potential failure of the v-port

segmented valve.

Close-fit spline or pin-key are available for stem-segment ball connection to providereliable transmission without motion lost or dead band.

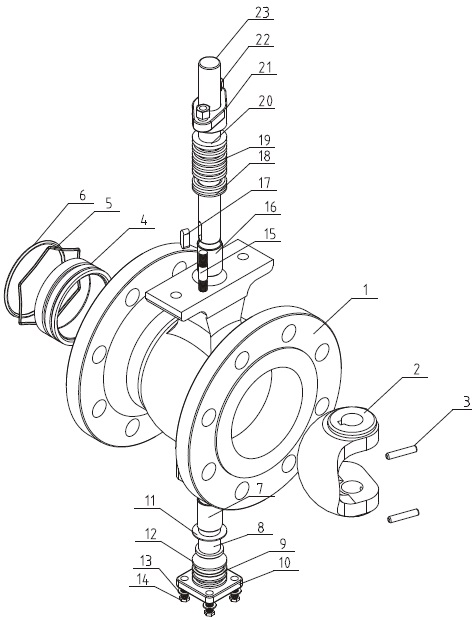

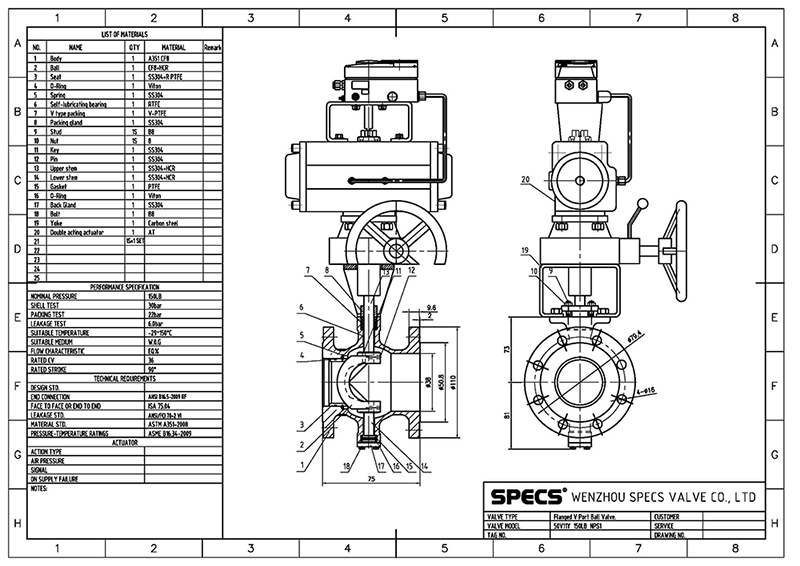

EXPLOSION VIEW OF V Port Ball Valve

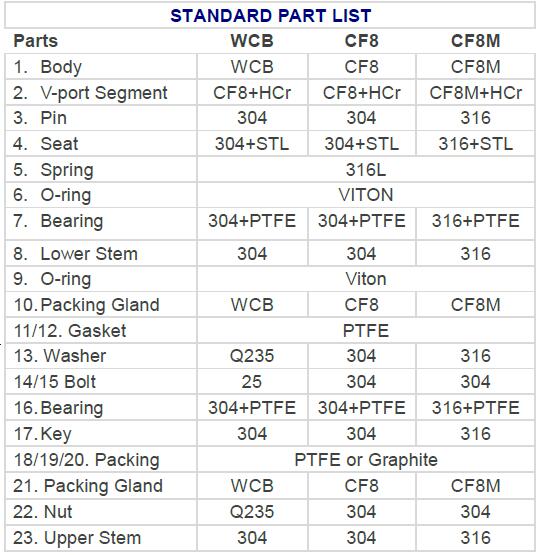

MATERIAL LIST OF V Port Ball Valve

Seat Options

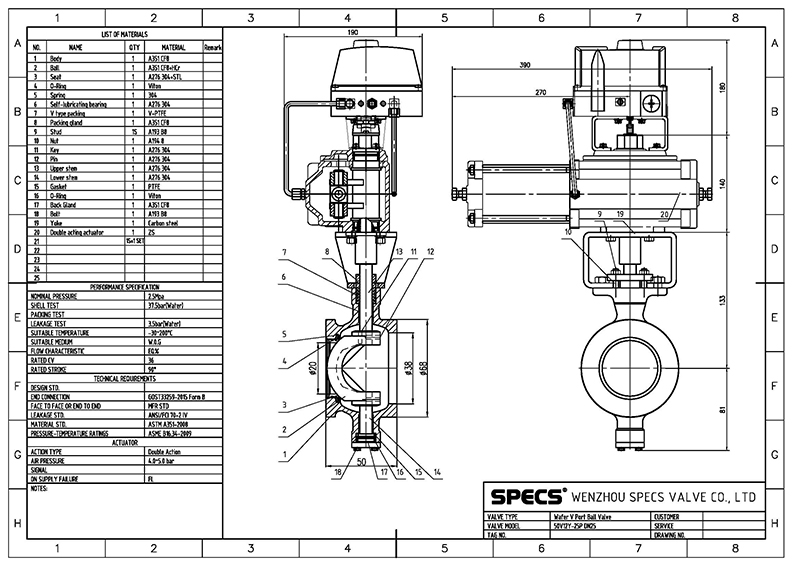

Flanged V Port Ball Valve

Wafer V Port Ball Valve