Description

Technical Specifications

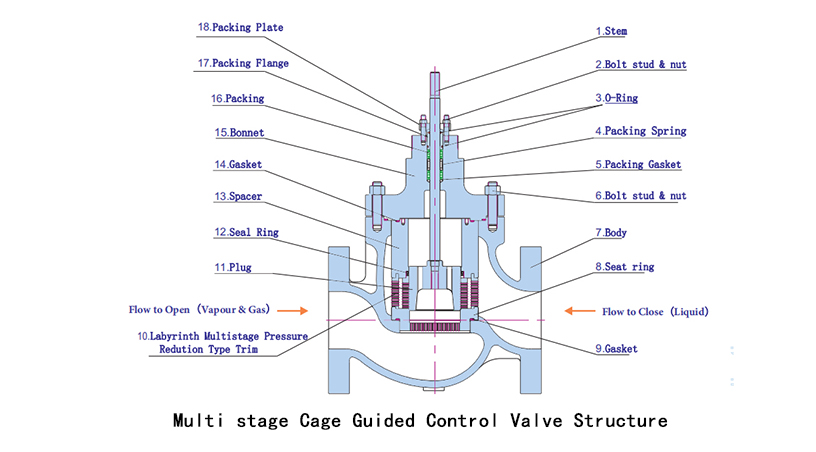

SPECS Multi Stage Cage Guided Control Valves are engineered specifically for critical anti-cavitation and low noise applications on liquids, gases or steam. Multi-stage controls flowing velocities in the valve trim by forcing the process fluid to follow a tortuous path of right-angle turns. The resistance to flow provided by these turns reduces fluid velocities significantly. Therefore, a vena contracta is never formed in the trim and noise and cavitation are stopped before they can start.

Note:This series can not been used in the medium contains large solid particles.

Applicable Standard

Design & Manufacture Standard: IEC 60534-2006

Face to Face: ISA-75.03-1992

End Connection: ASME B16.5, EN1092-1, GOST33259, ASME B16.25

Test Standard: IEC60534-4

Products Range

Size: 1 1/2"~24"

Pressure Rating: ASME CLASS 150~2500

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: Flanged (RF, RTJ), Butt Weld, Socket Weld.

Temperature Range: -196℃~550℃

Seat Leakage: ANSI Ⅳ(0.01%) or Ⅵ(bubble-tight)

Bonnet Type: Standard, Fin-Extension, Long-Extension, Bellows, Steam Jacket

Design Features

1. Multi Stage Cage Guided Control Valve is not applicable for the fluid of slurry and viscous fluid including particles and impurities due to its small cage channel.

2. By reducing pressure and velocity through multi-stage plug, this valve is applicable for high pressure difference situations.

Benefits

1. Multi Stage Cage Guided Control Valve is mainly applied for flow control in critical conditions including high temperature and high pressure or high pressure difference.

2. Multi Stage Cage Guided Control Valve can prevent fluid cavitation and flashing, reduce noise and erosion of valve trim due to high flow velocity.

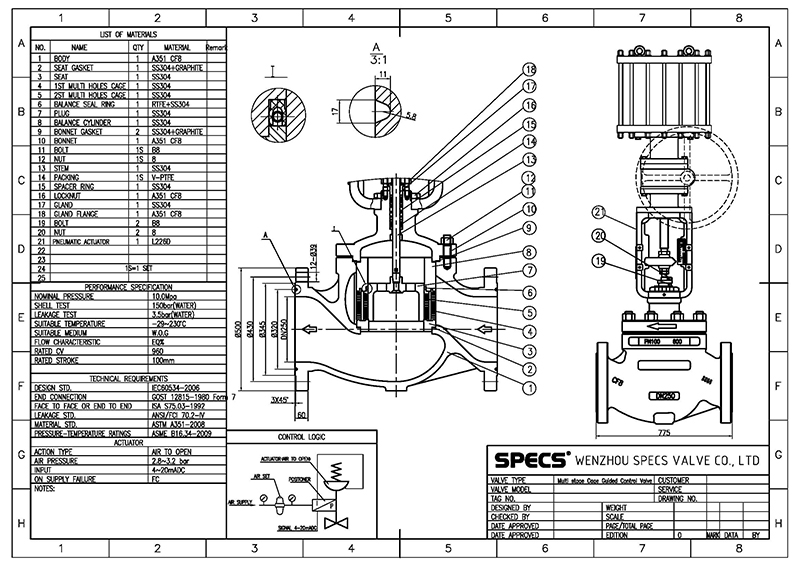

The GA Of Multi stage Cage Guided Control Valve

Body part selection map