Seat Leakage Of Control Valve

Update time: 22-01-09 Views: 2435

The Control Valve is the most used terminal control element in industrial production, which often determines whether the process control is timely and effective. If the Control Valve appears failure, the control loop will be forced to interrupt the control operation, which may lead to greater system failures, safety risks and incalculable economic losses. Among all control valve failures, the inability to close tightly and the seat leakage exceeding the specified value is one of the most worrying problems for users.

The seat leakage of control valve is an important factory inspection item, and it is also the test focus before the installation of the control valve and the guarantee basis for the online functional safety. Manufacturers, designers and users pay special attention to this.

Although there are clear standards and specifications, there are still many people among control valve manufacturers, designers and users who are a little vague about the seat leakage and the testing procedure of the control valve, and confuse the rated flow coefficient of the valve with the rated capacity of the valve. Errors frequently occur in the calculation of valve rated capacity. This article attempts to explain the current standards, inspections and routine tests for control valve seat leakage, valve rated capacity, maximum allowable seat leakage and its calculation.

Current international standards for control valve seat leakage are:

(1) IEC 60534-4-2006 "Industrial-process control valves - Part 4: Inspection and routine testing".

IEC standards are widely adopted by various countries, manufacturers and users, and the WTO agreement requires that each member state should be based on international standards to avoid technical barriers. For industrial control valves, currently only the IEC organization has issued a series of standards, which are approved by the European Union and most countries.

Adopted by standardization organizations. When IEC 60534-4-2006 (version 3.0) was released, it was quickly revised and adopted by many countries and standardization organizations, such as the European Organization for Standardization and its member states: EU EN 60534-4-2006, British BS 60534 -4-2006, Germany DIN EN 60534-4-2007, etc. In Asia, there is Japan's JIS B2005-4:2008.

(2) ANSI/FCI 70-2-2006 "Control Valve Seat Leakage".

The latest 2006 edition of this ANSI/Fluid Control Institute FCI standard was revised to align with IEC 60534-4-2006, replacing the obsolete ANSI/FCI 70-2-2003. Although the original IEC 60534-4 was based on FCI 70-2 and ASME B16.104, it is now ANSI/FCI to align with the IEC standard.

According to ANSI/FCI 70-2-2006. ANSI/FCI 70-2-2006 and reiterates that this standard applies to modulating and self-operated control valves, excluding on-off control valves. If it is for shut-off isolation or tight shut-off applications, it is recommended to follow the American Petroleum Organization API 598 Standard "Valve Inspection and Testing" Valve Inspection and Testing".

Control valve seat leakage

The seat leakage of control valve refers to the flow rate of the test medium flowing through the closed state control valve under the specified test conditions. The test medium is liquid (water) or gas (clean air or nitrogen) at room temperature.

Test conditions include adjusting the actuator to meet specified operating conditions and applying the required valve closing thrust or torque, the test medium applied to the normal or specified inlet of the valve body, the outlet of the valve body open to the atmosphere or a measuring device connected to the low pressure loss and the outlet to the atmosphere, etc.

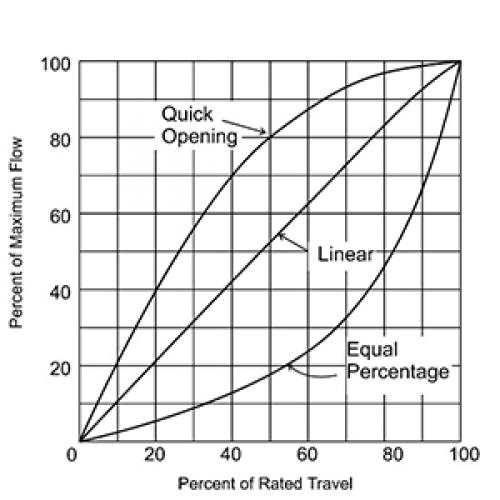

The leakage of the control valve seat is related to the leakage grade, test medium and test procedure, valve rated flow coefficient and valve rated capacity.