Introduction Of Control Valve Actuator

Update time: 21-08-21 Views: 1344

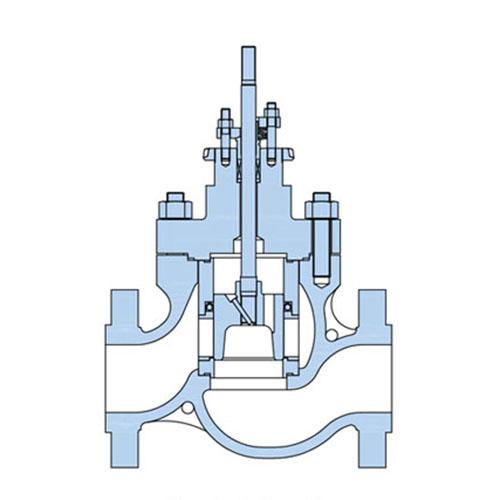

The Control Valve consists of two parts: the valve body part and the actuator. The actuator is an important part of the Control Valve. Different actuators have different characteristics. When selecting the type of actuator, in addition to the functionality, the energy and power supply on the spot should also be considered. Control valve manufacturers must fully understand the different characteristics of various actuators before they can provide users with a reasonable selection.

Actuator Type:

Classified according to different driving energy

2. Electric actuator

3. Electric -Hydraulic actuator

Classified according to different action

1. Linear motion

2. Rotary motion

Pneumatic actuator is the most commonly used type of actuator. It uses compressed air as the power source and has the characteristics of fast action.

Pneumatic actuators are usually equipped with a handwheel operating mechanism, which is mainly used for operation when the air source fails; the handwheel operating mechanism can be divided into a top-mounted handwheel operating mechanism and a side-mounted handwheel operating mechanism according to the installation position.

The choice of the two handwheels mainly depends on the installation space on site. Generally, if the axial installation space is sufficient, we prefer to use the top-mounted handwheel operating mechanism.

Pneumatic actuators also need to be matched with pneumatic accessories to achieve the purpose of on-site control.

Pneumatic accessories

Commonly used pneumatic accessories include positioner, air filter, solenoid valve, limit switch, volume booster, lock valve, pneumatic control valve, Valve Position Transmitter, quick exhaust valve, air storage tank, etc. The main function of accessories is to cooperate with pneumatic actuators to achieve various control requirements.

The meaning of pneumatic accessories:

1. The pneumatic control valve can be equipped with various accessories to achieve multiple control functions.

2. The accessories can meet various special requirements of the control system for pneumatic control valves.

3. The function of the accessory is to make the function of the pneumatic control valve more perfect, more reasonable and more uniform.

Electric actuator

The electric actuator uses the power source as the driving force to drive the motor to move, and then output force or torque through a certain conversion. When choosing an electric actuator, the two most important parameters are the power supply and the output force or torque. Sometimes you need to pay attention to the explosion-proof level and the protection level.

Electric-Hydraulic actuator

The electro-hydraulic actuator is a type of actuator that has developed relatively fast in recent years. It mainly consists of three modules: a motor part, a hydraulic part, and a control part. The control part drives the motor to move by receiving a 4-20mA current signal, the motor drives the hydraulic pump to work, and the hydraulic pump drives the actuator to move.

The advantage of electro-hydraulic actuator is that its transmission speed is faster compared with electric actuator, and its output force is larger than pneumatic actuator, so it has a very good development prospect in the future.