What is a control valve

Update time: 21-05-16 Views: 1182

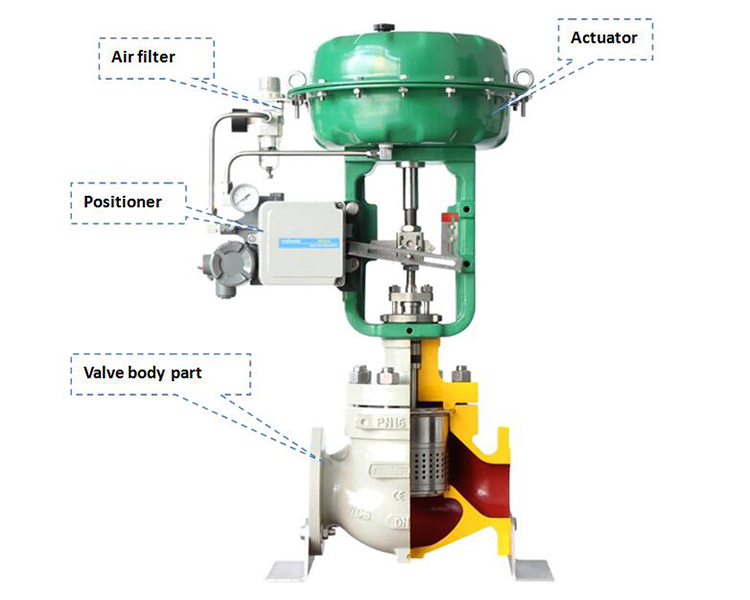

A Control Valve consists of a valve body, actuator, positioner, and accessories.

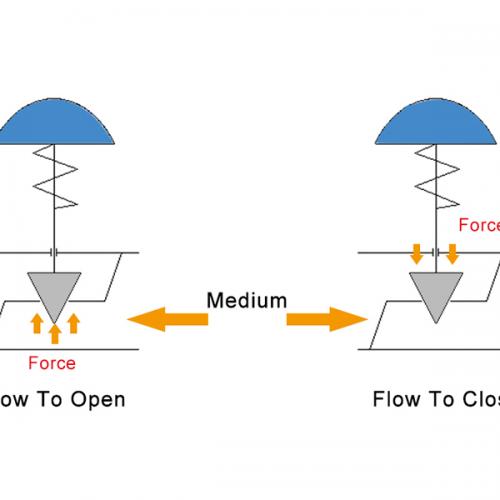

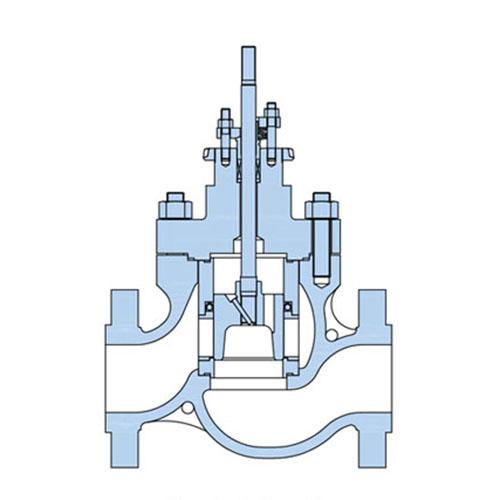

The valve body part is the regulating part of the Control Valve. It directly contacts the medium, the actuator drives the plug movement to change the throttle area between the plug and the seat to achieve the purpose of adjusting the process parameters (pressure, flow, temperature). The actuator(Pneumatic, Electric, Electric-Hydraulic) is the control device of the control valve, it provides the force to open and close the valve, the position of the valve plug or disk is changed by an actuator.

Positioners monitor and control true actuator movement to maintain a desired set-point. Accessories include electro-pneumatic transducers, pressure regulators, hand wheels, position indicators, and limit switches.

Importance of control valves

1. Installed at the production site, always in contact with the medium, working in harsh conditions such as high temperature, high pressure, deep cold, strong corrosion, easy to wear, easy to block, and easy to leak

2.It is the weakest link in the control system. Due to improper selection or poor maintenance, the entire automation system often cannot work reliably. In severe cases, it will cause the device to stop and the factory to stop production.

3. Closely related to the production process, it directly affects the material balance and energy balance in the production process

4. The control valve replaces manual operation, so people often call it the hands and feet that realize the automation of the production process.