Description

Technical Specifications

SPECS Single Seated Control Valve have a top guided unbalanced trim structure,It is a compact and simple structure, easy operation and maintenance which can be used under various applications, especially under normal pressure and normal pressure drop. Valves of this type are the most economical and reliable. Valve trim of unbalanced structure only applies to lower pressure drop.

Applicable Standard

Design & Manufacture Standard: IEC 60534-2006

Face to Face: ISA-75.03-1992

End Connection: ASME B16.5, EN1092-1, GOST33259, ASME B16.25

Test Standard: IEC60534-4

Products Range

Size: 1/2" ~ 8"

Pressure Rating: ASME CLASS 150~2500

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: Flanged (RF, RTJ), Butt Weld, Socket Weld.

Temperature Range: -196℃~550℃

Seat Leakage: ANSI Ⅳ(0.01%) or Ⅵ(bubble-tight)

Bonnet Type: Standard, Fin-Extension, Long-Extension, Bellows,Steam Jacket

Design Features

1. Top oriented action and low flow resistance design

2. Especially suitable for occasions with small pressure difference and can be applied to non-cavitation liquid and gas with noise in the specified range

3. Small size, light weight, simple flow with big capacity in the valve body

4. Especially suitable for controlling medium flow with suspended solids and granular. Avoid coking, bonding, blocking,with good control of high viscosity liquids and slurries

5. By using special materials (carbide, ceramics etc.) for valve trim and various surface treatment technology (nitriding, hardening treatment), valve can be used for a variety of harsh conditions

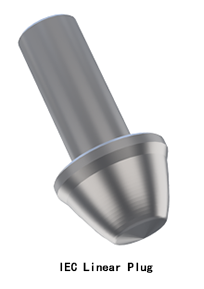

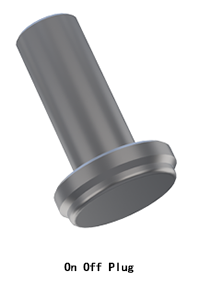

6. Plug with precise design makes valve flow to be almost perfect equal percent and linear, so that the valve has a high precision, high performance controlling function

Benefits

1. High sealing performance, cost-effective

2. Non-pipeline connection can be used for actuator and positioner, with high speed installation, high reliability and small installation space. Can be equipped with multi-spring Pneumatic Diaphragm Actuator or electric mechanism

3. Removal and installation of valve body and trim is simple and this makes future detection and maintenance easier

4. The parts commonality are improved and the product cost of manufacturing and maintenance are reduced due to the modular design of the valve trim.

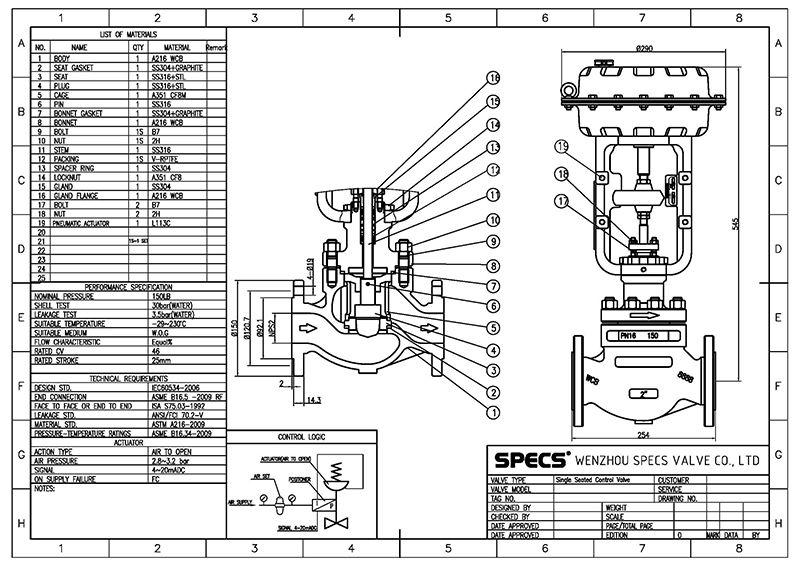

The GA Of Single Seated Control Valve

Body part selection map

Various flow characteristics are optional

Soft seat structure

The selction of control valve bonnet

Control valve bonnet is a part located between the actuator and the valve body assembly, Its main function is to prevent media leakage and connect the actuator. In order to adapt to different temperature and different medium sealing requirements, There are 5 common bonnet forms as follows:

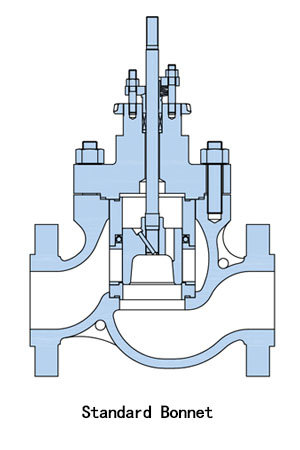

Standard Bonnet

Standard bonnets are suitable for normal temperature applications.

Recommended working temperature range: -20 to +230°C

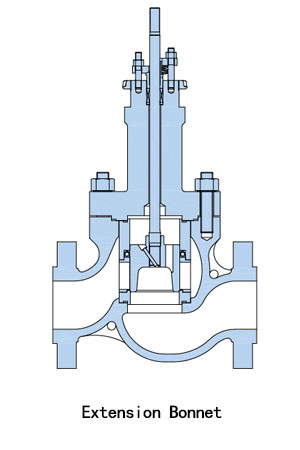

Extension Bonnet

Extension bonnets are used for either high or low

temperature service to protect valve stem packing from extreme process

temperatures.

Recommended working temperature range:-60 to +450°C

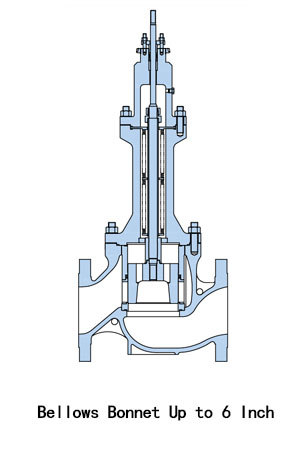

Bellows Bonnet

Bellows Bonnets are often used when the process fluid is toxic, volatile, radioactive, or highly expensive.

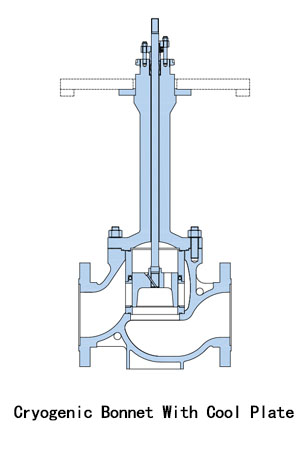

Cryogenic Bonnet

Cryogenic Bonnets are used for low temperature working

condition, especially for LNG(liquid natural gas).

Recommended working temperature range: -196 to -60°C

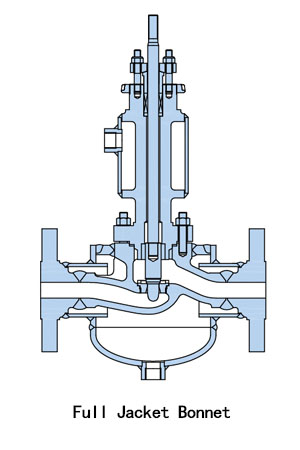

Jacket bonnet

Jacket bonnets are mainly used for high viscosity medium that will solidify at room temperature.