Description

Technical Specifications

SPECS Pneumatic Fluorine Lined Control Valve provides globe type Control Valves for controlling corrosive and/or poisonous fluids. The body cavity, valve plug, valve seat, valve stem are all lined with material F46 or PFA in thickness of 2.5 - 3mm to resist acid, alkali and strong corrosion.The valve is suitable for controlling medium with strong acid, strong alkali, volatile, easy penetration, so it is widely applied in industrial automation device with special media control system, including chemical, petroleum, metallurgy, medicine, textile etc.

Applicable Standard

Design & Manufacture Standard: IEC 60534-2006

Face to Face: DIN 3202-1999 F1

End Connection: ASME B16.5, EN1092-1, GOST33259

Test Standard: IEC60534-4

Products Range

Size: 1/2"~8"

Pressure Rating: ASME CLASS 150

Lined material: F46, PFA,PTFE

End: Flanged (RF)

Temperature Range:-40℃~200℃

Seat Leakage:ANSI IV or ANSI Ⅵ(bubble-tight)

Bonnet Type: Standard, Bellows

Design Features

1. With double sealing characteristics of PTFE bellows seal and V type PTFE packing seal, to prevent medium leakage

2. The lining material F46 and PFA can be used to get the maximum temperature resistance of 140 and 200 degrees Celsius

3. Hastelloy alloy plug, valve stem and valve seat can be used to ensure valve service life in case that the valve plug and valve seat lined with material F45/PFA is not able to meet the required hardness in occasions of flash and cavitation

Benefits

1. Corrosion resistance - body cavity, valve plug, valve seat, valve stem are all lined with material F46 or PFA in thickness of 2.5 - 3mm to resist acid, alkali and strong corrosion.

2. Small leakage - the leakage is lower than national level IV standards due to the soft seal of plug and seat.

3. Small and multi-spring actuator, small size, light weight and high precision adjustment.

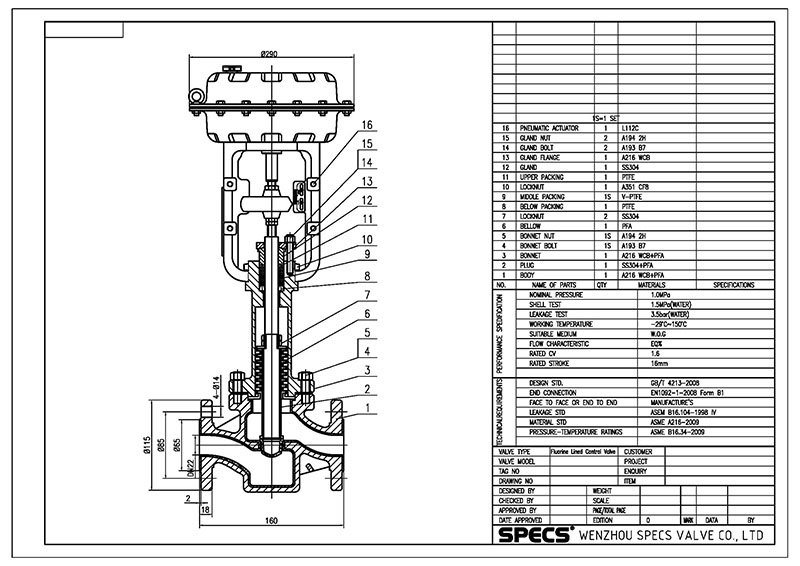

GA Of Fluorine Lined Control Valve