Description

Technical Specifications

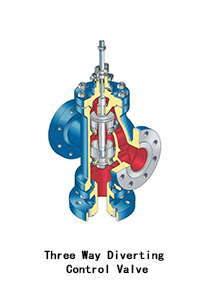

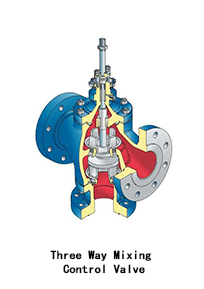

SPECS Three Way Control Valves are suitable for diverting one fluid flow into two flows or mixing two fluid flows into one flow through a three way valve.

With control of the three way valve, when one flow area between the plug and the valve seat increases, the other one would decrease. Mixing Control Valve is mainly used for mixing two fluids into a third fluid. Diverting Control Valve is mainly used for diverting one fluid into two fluids.

Applicable Standard

Design & Manufacture Standard: IEC 60534-2006

Face to Face: Manufacturer's Standard

End Connection: ASME B16.5, EN1092-1, GOST33259, ASME B16.25

Test Standard: IEC60534-4

Products Range

Size: 1 1/2"~24"

Pressure Rating: ASME CLASS 150~600

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: Flanged (RF, RTJ), Butt Weld, Socket Weld, Thread.

Temperature Range: -196℃~550℃

Seat Leakage:ANSI IV or ANSI Ⅵ(bubble-tight)

Bonnet Type: Standard, Extension ,Long-Extension,Bellows,Steam Jacket

Design Features

1. Un-balanced plug structure, mainly used for control of 3-way diverting or mixing occasions, can not take too much close pressure difference.

2. Leakage would be increased when the fluids flowing through the 3-way valve are with different temperature, because the degree of expansion of valve plug and seat are different. So normally, the two fluid temperature difference should not be more than 150℃.

Benefits

1. Product costs and installation space can be reduced when using this series for fluid proportion control system, because it covers air-open and air-close control valves.

2. This series is suitable for diverting one fluid flow into two flows or mixing two fluid flows into one flow through a three-way valve.

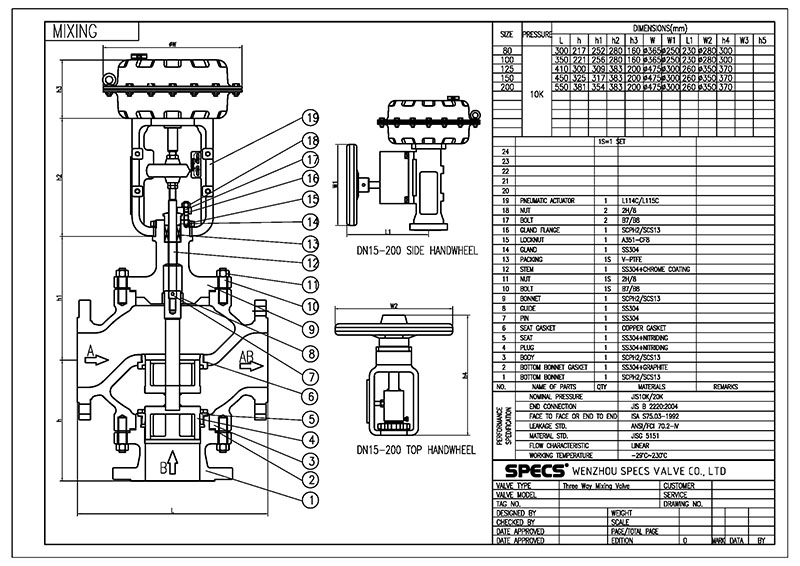

GA Of 3 Way Mixing Valve

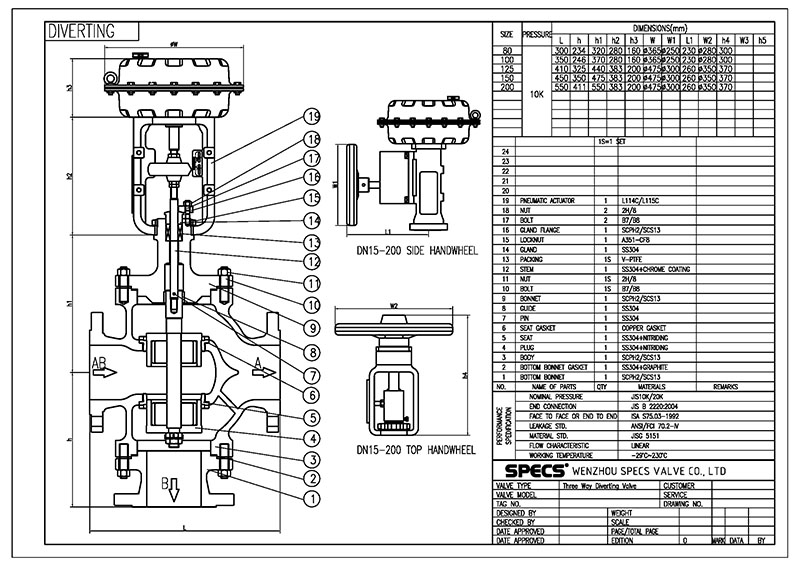

GA Of 3 Way Diverting Valve