Description

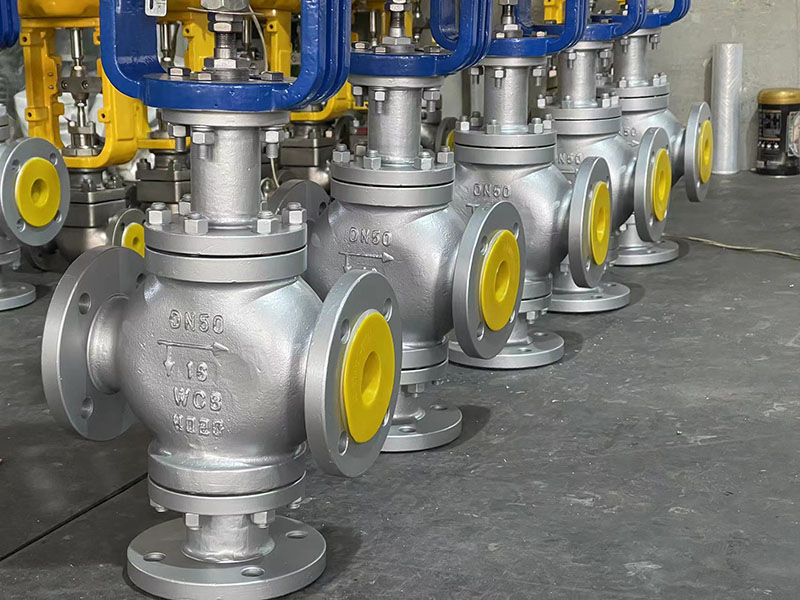

SPECS Three Way Control Valves are suitable for diverting one fluid flow into two flows or mixing two fluid flows into one flow through a three way valve.

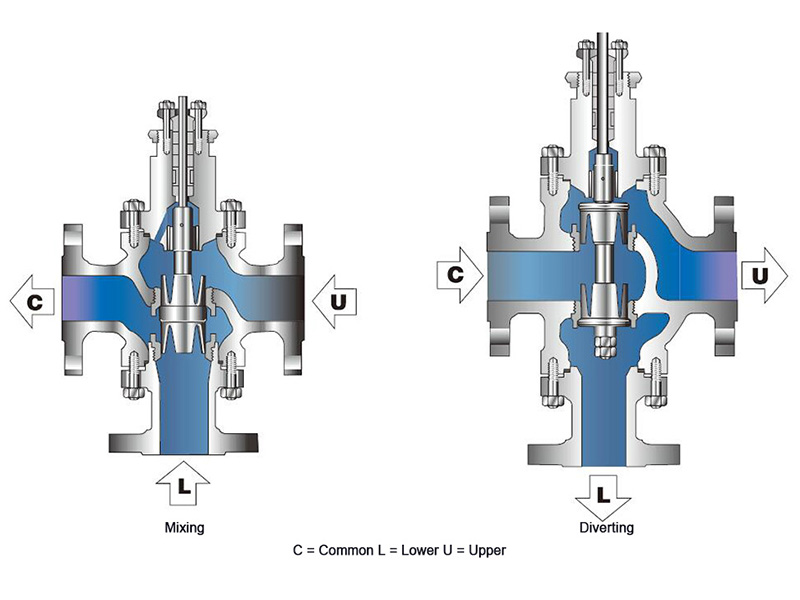

With control of the three way valve, when one flow area between the plug and the valve seat increases, the other one would decrease. Three Way Control Valve can be divided into mixing type and diverting type. Mixing type control valve is mainly used for mixing two fluids into a third fluid. Diverting type control valve is mainly used for diverting one fluid into two fluids.

Applicable Standard

Design & Manufacture Standard: IEC 60534-2006

Face to Face: Manufacturer's StandardEnd Connection: ASME B16.5, EN1092-1, GOST33259, ASME B16.25

Test Standard: IEC60534-4

Products Range

Size: 1 1/2"~24"

Pressure Rating: ASME CLASS 150~600

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: Flanged (RF, RTJ), Butt Weld, Socket Weld, Thread.

Temperature Range: -196℃~550℃

Seat Leakage:ANSI IV or ANSI Ⅵ(bubble-tight)

Bonnet Type: Standard, Extension ,Long-Extension,Bellows,Steam Jacket

Design Features

Three Way Control Valve designed for either mixing or diverting service. Standard features include:

Heavy GuidingConstruction of SPECS Three Way Control Valve includes top guiding in the plug, as well as guiding within the seat ring locations providing an extremely well supported and stable design.

High Capacity

Large flow galleries provide high capacity designs with low pressure recoveries. High critical flow factors are attained in both combining and diverting configurations.

Flow Stability

Three Way Control Valve is a dual seated design with flow tending to open the valve at both ports. This provides inherent dynamic stable resulting in excellent throttling control performance.

Wide Operating Range

Designs are available in various sizes and can be configured to operate within an extremely wide temperature range. This is accomplished through use of high performance materials and design configurations.

Benefits

1. Product costs and installation space can be reduced when using this series for fluid proportion control system, because it covers air-open and air-close control valves.

2. This series is suitable for diverting one fluid flow into two flows or mixing two fluid flows into one flow through a three-way valve.

Description:

The plug structure of Three-way control valve is designed to flow to open. If valve plug in the valve seat that is mixing service control valve. There are two input ports and one outlet port. The valve plug is located on the outside of the valve seat that is diverting service control valve. There is one inlet port and two outlet ports. Due to the three-way control valve have opening and closing operation at the same time, so three-way control valve doesn’t have air to open or air to close such type.

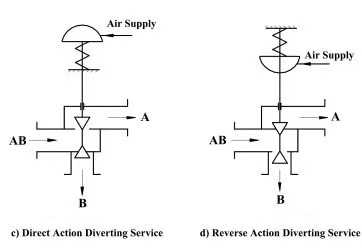

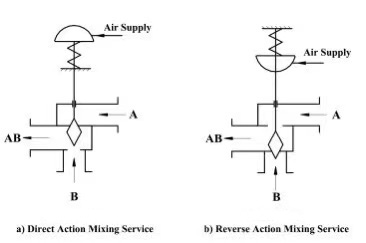

• For Direct Action Mixing Service, air failure means vertical pass(B → AB). But for Reverse Action Mixing Service, air failure means the flow is a horizontal pass (A → AB)

• For Direct Action Diverting Service, air failure means horizontal pass (AB → A). But for Reverse Action Diverting Service, air failure means the flow is a vertical pass(AB → B)