Description

Technical Specifications

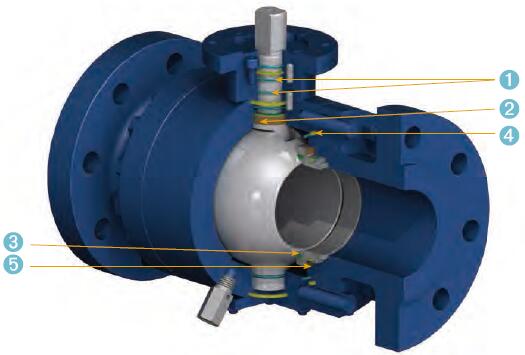

SPECS forged trunnion mounted Ball Valve has two or three body structures, the middle flange is connected by bolts, and the sealing is made of reinforced PTFE inserted into the stainless steel ring. The spring is set at the back of the ring to ensure that the seat is close to the ball and keep the sealing. PTFE bearings are installed on the upper and lower valve stems to reduce friction and save labor. The bottom of the small shaft is equipped with adjusting plates to ensure the contact position between the ball and the sealing ring. Full diameter: the valve flow diameter is the same as the inner diameter of the pipeline for pipeline cleaning.

Compared with cast body,the forged body is much better quality with fewer defects but also much more expensive than cast body.

Applicable Standard

Design & Manufacture Standard: API6D, ASME16.34, BS5351

Face to Face: ASME B16.10, API6D

End Connection: ASME B16.5, EN1092-1, GOST33259, ASME B16.25

Test Standard: API6D, API598

Products Range

Size: 2"~48"

Pressure Rating: ASME CLASS 150~2500

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: RF, RTJ, BW

Operation: Operation: Manual, Gear, Pneumatic, Electric

Design Features

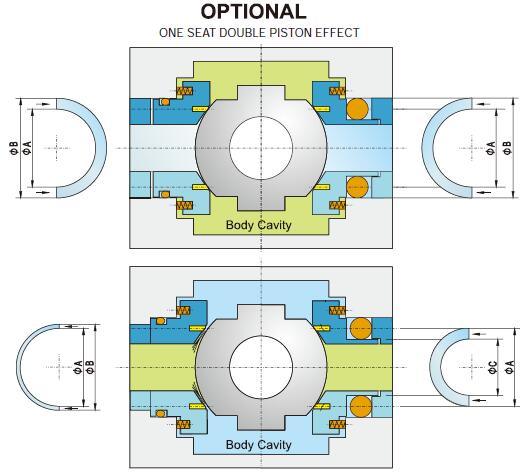

Self Relieving Seats (single piston effect)

The single piston effect is the the standard design for trunnion mounted Ball Valves. Pressure from both upstream and downstream sides pushes the seat rings against the ball. If the force created by the body cavitypressure is greater than the preloaded spring force plus the force created by the pressure from upstream or downstream side, the seats are pushed away from the ball. Thus, any overpressurein the body cavity is released automatically in the valves' fully open or fully closed position.

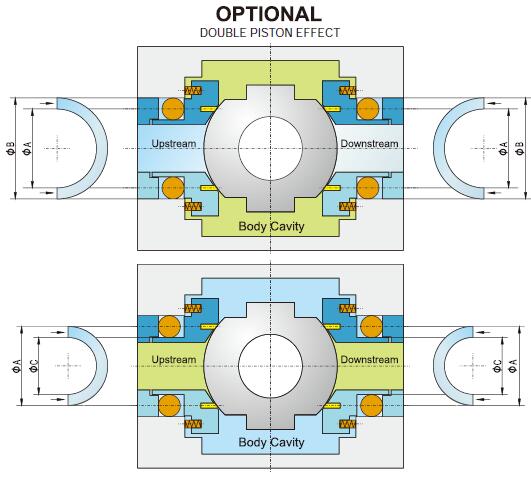

Double Piston Effect Seats (DIB-1)

Double piston effect seats are pressure

energized in both directions.So the seat rings are always pushed against the

ball by the pressure from upstream/ downstream or from the cavity.

If the upstream seat fails, the downstream seat can still ensure a tight seal. pipe pressure testing. Since double piston effect valves do not have the selfrelieving function, the automatic cavity-pressure relief valve shall be provided, unless otherwise agreed.

One Self-Relieving Seat and One Double

Piston Effective Seat (DIB-2)

If the force created by the body cavity pressure is greater than the preloaded spring force plus the force created by the pressure from pipeline, the cavity pressure releases via the self-relieving seat, the double piston effect seat still functions a tight seal.

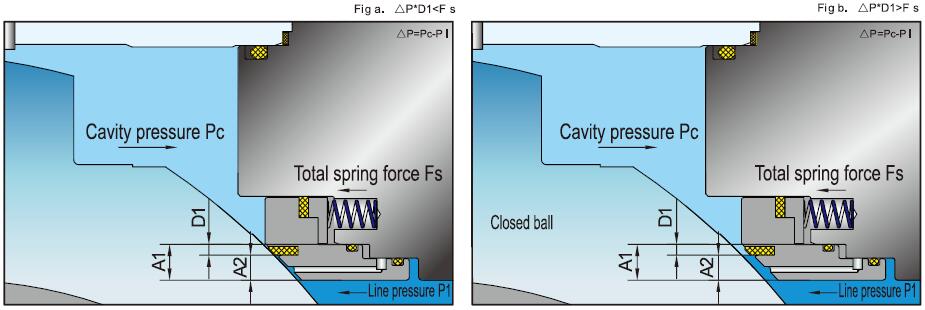

Cavity Pressure Relief

When force created by cavity pressure (Pc) is lower than the force created by line pressure (PI), i.e. AP*D1 <Fs, then contact between ball and seat ring is assured to provide a tight seal.

When cavity pressure is higher than seat spring force plus line pressure, i .e. P*D1 >Fs, the self relieving action allows the valve seat to move slightly away from the ball surface. Therefore, any overpressure inside the body cavity is discharged into the pipeline to restore thebalance between the body cavity and the pipeline(either upstream or downstream side).

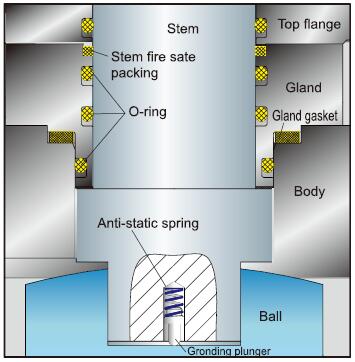

Anti Blow-out Stem

The stem is made separately from the ball. The lower end of the stem is designed with an integral shoulder to be blowout-proof.

Anti-static Device

The Antistatic Device is a standard feature of the SPECS ball valve. A spring-loaded pin assures the electrical continuity between the ball, stem and body, to avoid sparking during the turning of the stem to open and close the valve.

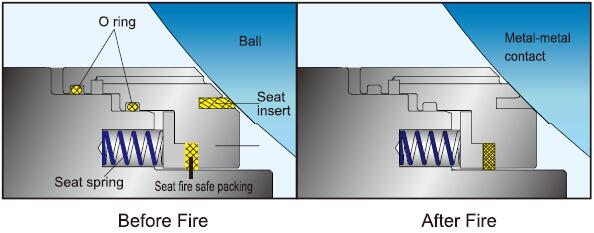

Super Fire safe design

Leakage from the valve stem area is prevented by two O-ring seals and a gland gasket. Leakage through the valve body connection is also blocked by an O-ring seal and a body gasket. After a fire deteriorated the O-rings, gland and body gasket, the firesafe stem packing prevents external leakage.

Internal leakage prevention

After the soft sealing materials are decomposed or deteriorated by fire, the edge of the metal seat preloaded by the seat spring comes into contact with the ball to shut off the process media and minimize internal leakage through the valve bore. Also the fire safe graphite packing is compressed by the seat spring to prevent process media leakage between the valve body and the seat.

Double block and bleed

In the closed position, each seat shuts off the process media independently on each side, or simultaneously on both sides of the ball, the cavity can be vented / bled via vent or drain plugs on the valve body.

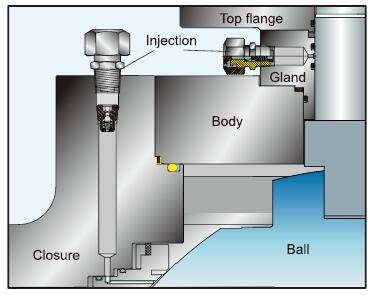

Emergency sealant injection system

For 6 inch and larger SPECS Trunnion mounted ball valves, sealant injection fittings will be installed on both the stem and seats. When the sealing materialsfsoft seat or the stem o-ring)are damaged, the seat and stem leakage can be prevented by the sealant injected into these fittings. The fitting shall include a Check Valve secondary means of sealing. For 4 inch and below, it could be added upon requirement.

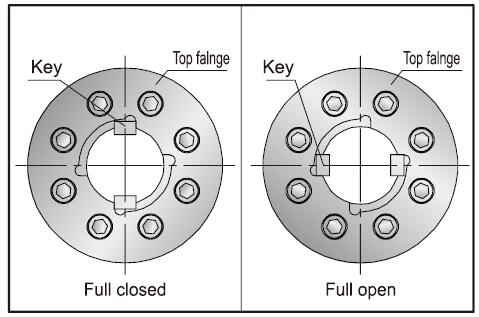

Internal stem stop design

During actuator installation, actuator's travel stop has to be adjusted according to the fully open and fully closed position of valve. This stem stop can help to find fully open and fully close position easily.

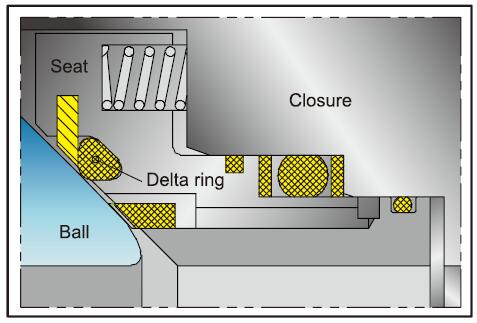

DELTA RING seat design (optional)

The material of delta ring is elastomer, which has better elasticity, can "absorb" the deviation in the ball, to obtain zero leakage easily, especially for large-sized ball or austenitic ball or full-welded ball valve. This is an optional design, not for standard.

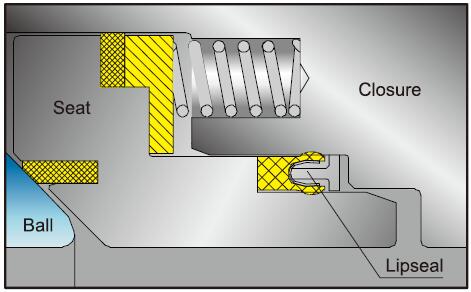

Lipseal design(optional)

Lipseal is the spring-energized seal including Elgiloy or Inconel spring and PTFE jacket. It's effective in a wide range of application, such as high resistance to corrosive chemical media, high sour gas, low temperature or cryogenic service.

Metal-to- metal seat design(optional)

When valve is applied in the high abrasive or high temperature service, metal-to-metal seat shall be chosen

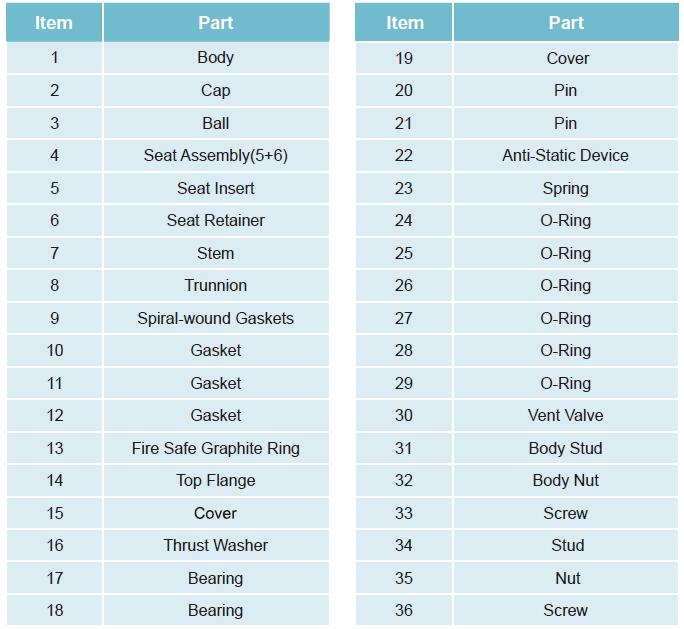

FORGED TRUNNION MOUNTED BALL VALVE

PARTS NAME OF FORGED TRUNNION MOUNTED BALL VALVE