Description

Technical Specifications

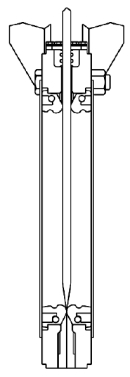

SPECS Slurry Knife Gate Valves are a bi-directional wafer valve equipped with two metal reinforced rubber sleeves. Twin rubber sleeves and push-through gate design facilitate self-cleaning and prevent media build up. The durable body is offered in a compact wafer style. When fully open, the valve bore offers no resistance to line media. It’s designed for demanding slurry applications.

How it Works:

The SPECS Slurry Knife Gate Valves are a push through design which discharges a minimum amount of process media when cycling between open and closed. Matching sleeves are placed in the valve housing to seal against the gate when the valve is closed and seal against each other when the valve is open. This tight seal contains the internal line pressure, precluding direct pressure against the secondary seal. As the gate moves from open to closed position, it separates the facing sleeves. The unique sleeve assembly provides positive sealing action when the valve gate is closed and when the gate is open; the sleeves provide an unobstructed port and protect metal parts from the flowing slurry.

Open position Mid-stroke Position Closed Position

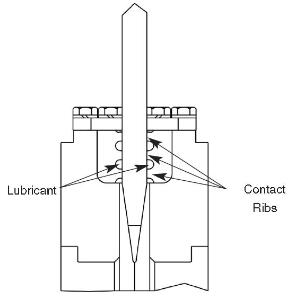

Secondary seal:

The one-piece, self-adjusting, molded elastomer secondary seal eliminates any leakage between the knife gate and top of the valve body in any orientation. The seal also prevents any outside contaminants from getting inside the valve. It is dynamically self-adjusting, eliminating the need for continual adjustment required with conventional style packing. The secondary seal is also used to lubricate the gate as it cycles through the seal, providing smoother gate movement and longer seal life, as well as reducing the force required to actuate the gate. Silicon-based lubricant is held inside a series of rib cavities built into the seal, each time the gate passes through the seal, a small amount of the long-lasting lubricant is released. The seal is replaceable and can be changed while the valve is in the line.

Applicable Standard

1. Design & Manufacture standard as to: ASME B16.34

2. Face to Face dimension standard as to: MFR-STD

3. Flange dimension conforms as to: ASME B16.5

4. Testing And Inspection as to: MSS SP-81

5. Pressure-temperature conforms as to: ASME B16.34

Products Range

Size: 2" ~ 24"

Pressure Rating: ASME CLASS 150

Working temperature: -29℃ ~ +100℃

Working pressure: ≤ 150 PSI

Suitable Medium: tough slurries, abrasives, and corrosive chemical applications

Body Materials: Cast Carbon Steel A216 WCB, Cast Ductile Iron ASTM A536

Sleeves Material: NR, EPDM

General applications

• Mining

• Power

• Pulp and paper

• Alumina

• Chemical

• Cement