Description

Technical Specifications

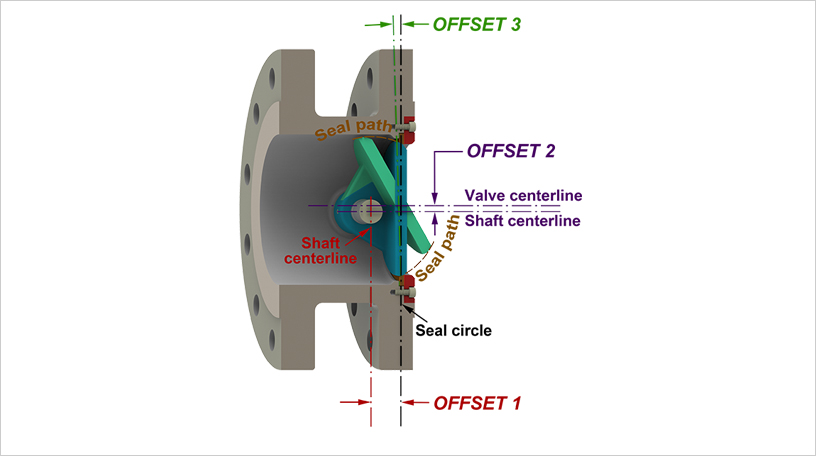

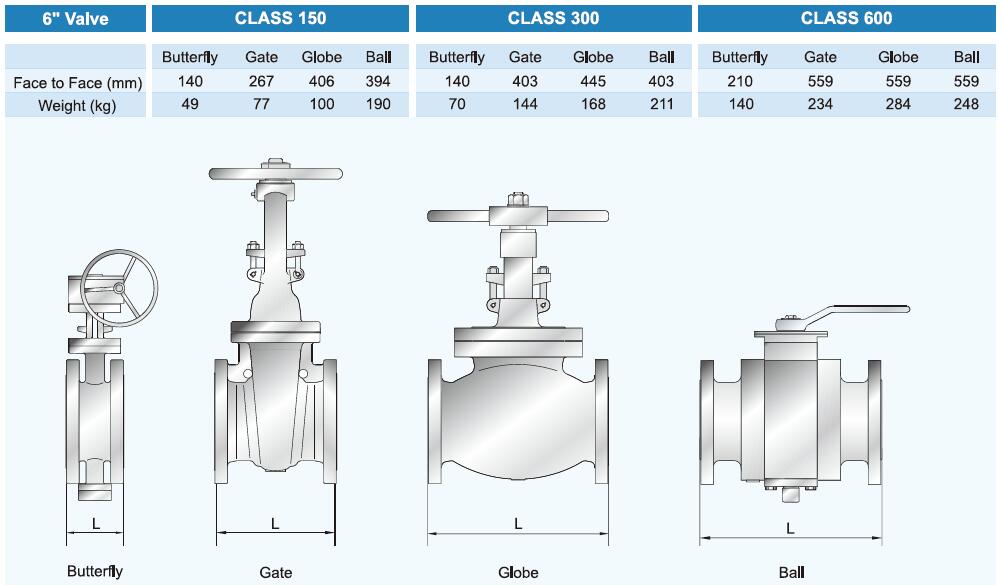

SPECS Triple Eccentric Butterfly Valve. The valve utilizes unique triple eccentric structure. Zero friction will emerge between the valve plate and the sealing ring. Triple-offset Butterfly Valves, shaft offset is created by designing the valve with the shaft located behind the centerline of the sealing surface (offset1) and slightly to one side of the pipe centerline (offset2). The third offset is point of intersection of tangents of seat and disc sealing deviating from the disc face. These offets are to completely eliminate all disc to seat friction throughout the valve’s entire 90 degrees of rotation. Metal seal, laminated seat are optional. The triple-offset provides ANSI ClassIV, V, VI leakage performance. The seat seal ring can be changed easily from the body.

Applicable Standard

Design & Manufacture Standard: API 609

Face to Face: API609, BS EN 558, DIN3202, ISO 5752

End Connection: DIN, BS, UNI, ISO, ANSI, AS, JIS

Test Standard: API598

Products Range

Size: 2"~40"

Pressure Rating: 150-600LB

Body: Carbon Steel, Stainless Steel, Nickel Aluminum Bronze

End: Wafer, Lug, Flange, BW

Operation: Manual, Pneumatic, Electric

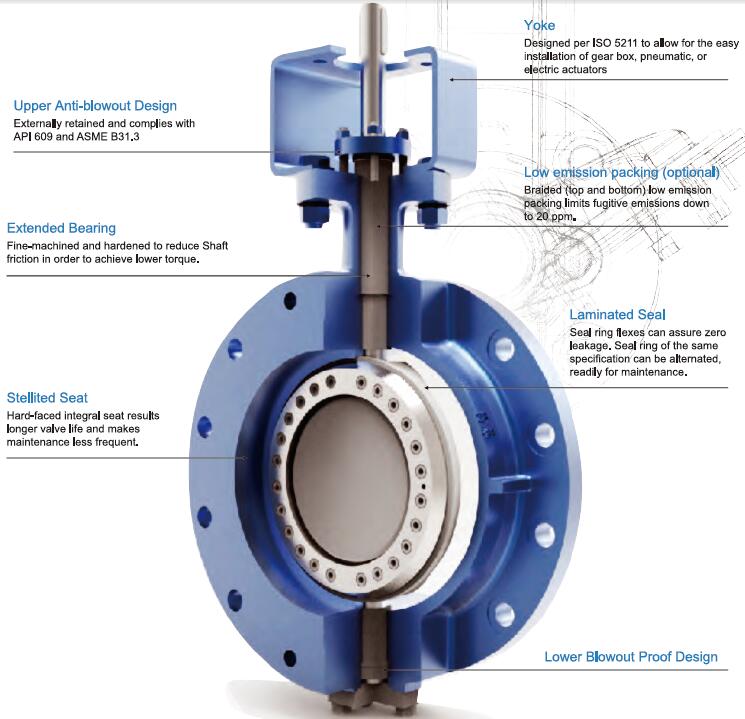

Design Features

Triple Offset Frictionless Design

Offset 1: The shaft is offset from seat

plane, allowing a continuous seating surface.

Offset 2: The shaft centerline is offset from disc centerline to lift the disc rapidly off and away from the seat when the valve is open.

Offset 3: The cone axis is offset from seal

centerline, eradicating disc-seat friction.

Low operating torque

SPECS Triple Eccentric Butterfly Valves combine three offsets with flexible laminated metal and graphite to assure a tight and uniform seal and reduce operating torque.

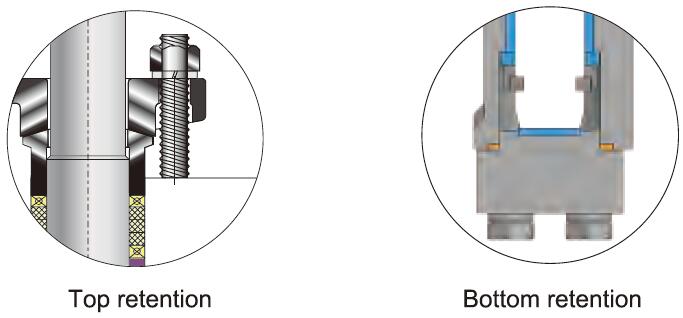

Anti-blowout Shaft

Double anti-blowout design satisfies API

609 and ASME B31.1 requirements through both internal and external stem

retention.

Top Retention: Packing gland follower retains the stem integral collar.

Bottom Retention: T shaped attachment prevents stem blow-out.

Zero Leakage

Laminated seal rings are designed to self align and allow valves to meet zero leakage per API 598.

Fire Safe Design

Triple Offset Butterfly Valves are not soft seated and can fulfill the fire-safe requirements of API 607.

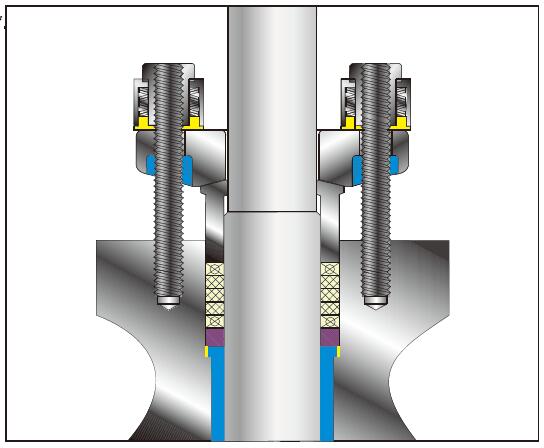

Low Emission Shaft Seal

SPECS can supply low-emission stem seal

with leakage rate up to 20 ppm*.

a.) Shaft is fully guided by shaft bearing

& gland follower to reduce side load due to line pressure thrust.

b.) The packing set is pre-corn pressed and

is a combination of braided graphite rings and die formed flexible graphite

rings.

c.) Controlled

Ra0.4~Ra0.8 finish on the shaft and Ra1.6 on the stuffing box provides optimum

packing and shaft sealing.

d.) Optional Live Loaded gland flange

available to provide constant packing compression to reduce fugitive emissions.

e.) Optional shaft seal design available

per Shell MESC 77/312 & TA-Luft.

* 20ppm per sniffing method with helium gas.

Compact Design

SPECS Triple Eccentric Butterfly Valves are designed to API 609 and offers flow control solution in a compact design. It provides a light weight solution to bulky gate, globe, and Ball Valves when space or weight are at a premium.

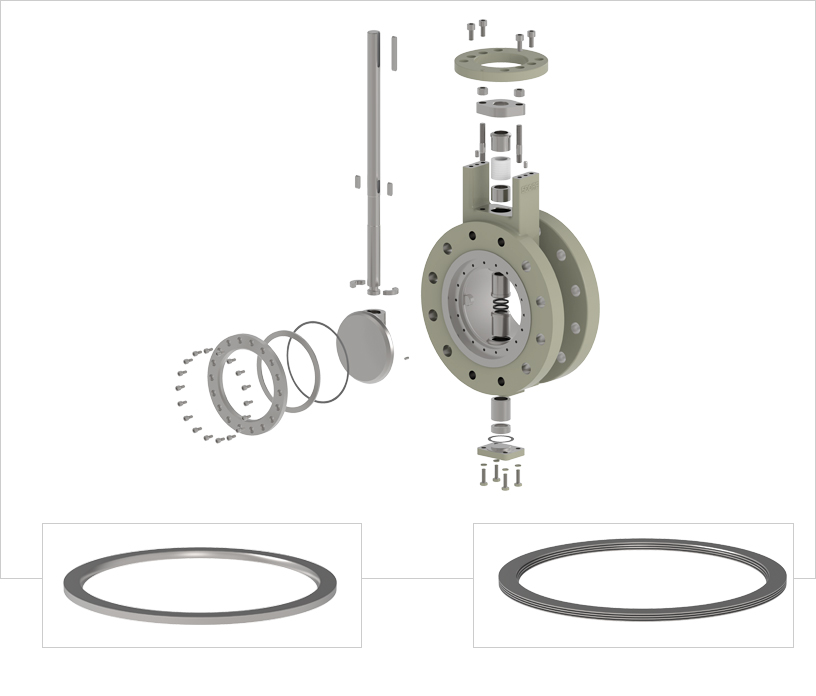

Triple Eccentric Butterfly Valve Construction

The Explosion View Of Triple Offset Butterfly Valve