Description

Technical Specifications

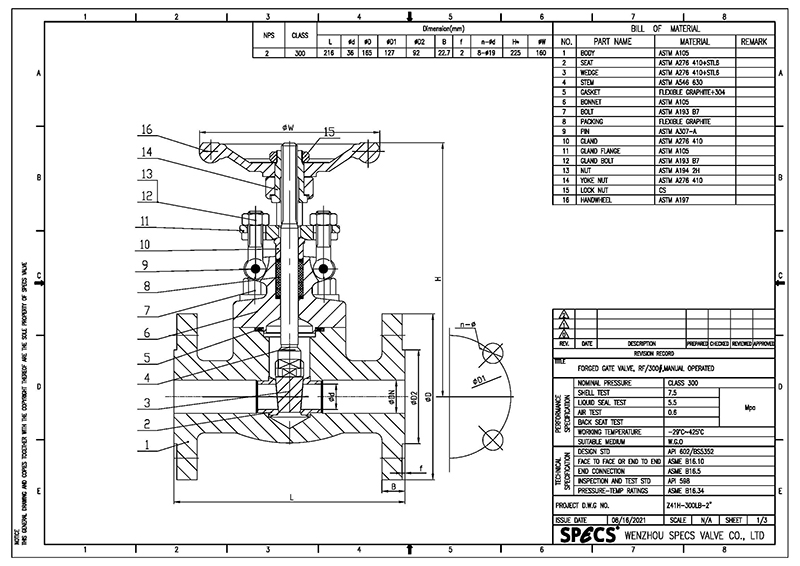

SPECS Bolted Bonnet Forged Gate Valves are suitable for small-diameter pipelines of Class 150 ~ 2500 and operating temperature of -29 ~ 425°C (carbon steel) or -29 ~ 500°C (stainless steel). Forged steel Gate Valves are used to shutoff or connect the medium in the pipeline. Different materials are selected, which can be respectively applied to water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea and other media .

Forged steel flange end gate valves have three bonnet designs. The first type is the bolted bonnet. According to this design, the valve body and the bonnet are connected by bolts and nuts, and spiral wound gaskets (made of 316 flexible graphite).

Products Range

Size: 1/2" ~ 2"

Pressure Rating: ASME CLASS 150~1500

Materials:A105,LF2,F91,F11,F22,F304,F304L,F316,F316L,F321,F51,Alloy steel etc.

Trim: Per API 602

Operation: Handwheel

Connection Type:Flange,Welding,Thread, Socket welding

Design Features

1. A positive backseat, high quality packing material and improved stuffing box design ensure

tighter stem seal.

2. The T-head stem design provides positive disc to stem connection and ensures effective

seating operation.

3. Fully guided solid wedge reduces wear on seating surfaces.

4. Stud and bolt arrangement facilitates packing maintenance.

5. Recessed Body-Bonnet Joint design captures the stainless steel spiral wound gasket

ensuring body/bonnet sealing integrity.

6. Rolled-in seat design ensures tight and effective seat assembly.

The GA Of Bolted Bonnet Forged Gate Valve