Description

Technical Specifications

SPECS Floating Ball Valve is mainly used to cut off or connect the medium in the pipeline.

Floating Ball Valve, the ball is floating, the sealing structure is the ball with two seats, one on the upstream and the other on the downstream side of the ball. The upstream pressure pushes the ball which compresses the downstream side seat to completely shut off fluid control. Floating Ball Valves are available in types of One Piece Uni-body, Two Piece Split Body & Three Piece Bolted Body.

Applicable Standard

Design & Manufacture Standard: API6D, ASME16.34, BS5351

Face to Face: ASME B16.10, API6D

End Connection: ASME B16.5, EN1092-1, GOST33259, ASME B16.25

Test Standard: API6D, API598

Products Range

Size: 1/2" ~ 8"

Pressure Rating: ASME CLASS 150~600

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: SW, BW, RF, RTJ, NPT, BSP, Speial

Operation: Operation: Manual, Gear, Pneumatic, Electric

Design Features

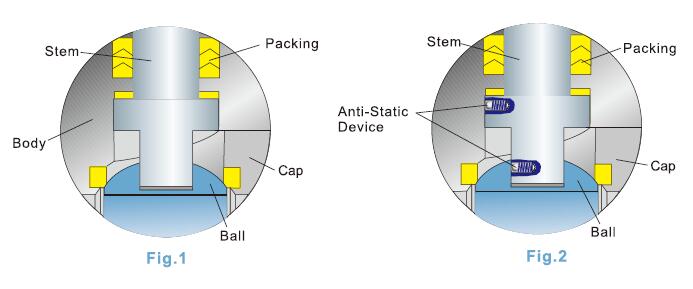

Blow-out Proof Stem

The lower end of the stem is T-shaped structured, protected by boss of body, which assures stem retention at any pressure acts as backseat.(Fig.1)

Anti-static Device

A spring-loaded plunger fitted on stem keeps constant contact between ball, stem and body to create an electric path to transfer charges, avoiding acceleration of static electricity as a result of friction during valve on-off. Such build-up is utterly hazardous to some services. (Fig.2)

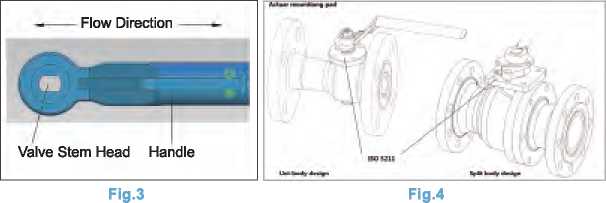

Position Indicator

Double D stem head design provides mounting of the lever always in parallel to the flow passage. Misalignment of the lever is thus prevented. (Fig.3)

Locking Device

Facility for mounting a locking device for prevention od accidental valve operation is provide.

ISO 5211 Actuator Mounting Pad

Ball valves always furnished with integral actuator mounting pad designed according to ISO 5211. (Fig.4)

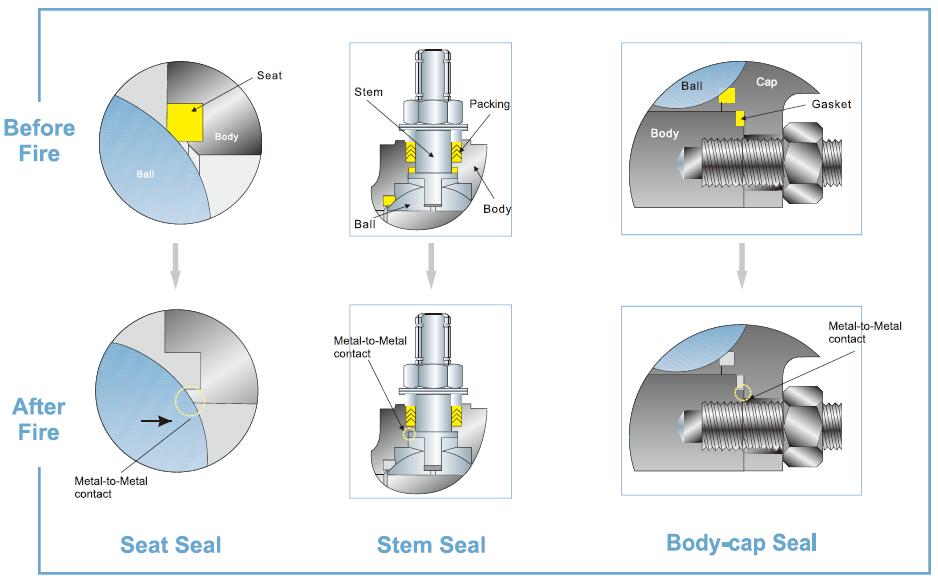

Fire Safe - Metal to Metal Sealing

When soft seats are decomposed or ruined by fire, the ball, driven by pressure, comes into contact with the metal lipseal seat of original soft seat, creating a metal-to-metal seal to shut off service fluids and minimize internal leakage.

Additionally, the fire safe metal seat prevents damage the medium imposed on soft seat and minimizes creep of nonmetal materials. All the SPECS floating valves are designed to be fire safe per API 607 and are tested and certified by the third party.

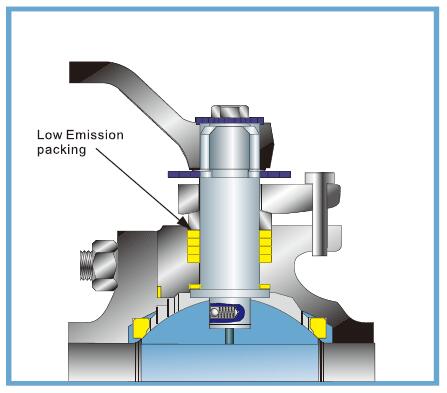

Low Emission Control

Modern industry sectors are challenged by valve fugitive emission to control service fluids released from the valve and curb environmental degradation. Therefore, emission control features SPECS floating ball valves Series. Low emission packing is assembled, whose max. leaking rate of design and test stands at 100 PPM (Test is performed according to IS015848)

Roughness control over stem and packing

Stem surface roughness is strictly restricted between Ra0.4 and Ra0.8, which ensures entry of graphite packing powder into tiny stem scratches to function as a lubricator, minimizing leakages around stem. Max. roughness of stuffing box is RA3.2, which is a proper value to hold packing ring in place and result in better sealing performance.

Low Emission Packing

The packing is combination of parallel and

vertical layer which is made of die-formed graphite ring processed by flexible

graphite, characterizing heat resistance, less stress relaxation and low creep.

The special structure means low friction on rotary stem, providing stabilized

seal capability for the valve for a long time under frequent functioning.

For low-temperature and cryogenic service, the standard V shape PTFE packing rings are installed for low emission control.