Description

Technical Specifications

SPECS Trunnion mounted Ball Valve is used to cut off or connect the media in various pipelines of Class150 to Class2500. The valves made of different materials are suitable for various media such as water, steam, oil, liquefied gas, natural gas,coal gas, nitric acid, oxidizer, urea and etc. The driving modes include manual operation, worm and worm gear transmission,pneumatic operation and electric operation. The connection ends can be flange or butt welding.

Cast Steel Trunnion mounted Ball Valves allow easy and smooth operation at high line pressure. Carefully aligned bearings assist low torque operation. The ball is fixed in position but free to turn. All Casted Trunnion Ball Valves are with reliable high quality castings and fire safe design certified according to BS 6755, API607 & API 6FA. Meet all applicable ASME standards.

Applicable Standard

Design & Manufacture Standard: API6D, ASME16.34, BS5351

Face to Face: ASME B16.10, API6D

End Connection: ASME B16.5, EN1092-1, GOST33259, ASME B16.25

Test Standard: API6D, API598

Products Range

Size: 2"~48"

Pressure Rating: ASME CLASS 150~2500

Material: Carbon steel, Stainless steel, Alloy steel, Duplex stainless steel

End: RF, RTJ, BW

Operation: Operation: Manual, Gear, Pneumatic, Electric

Design Features

Emergency

Sealant Injection Fitting: Prevents leakage from the stem.

Blow-out

Proof Stem: Stem functions as the backseat to assure stem sealing at all

pressures.

Emergency

Sealant Injection Fitting: Prevents leakage from the seat.

Drain

plug : Relieves the body cavity.

Double

Sealing O-rings: Prevents leakage from stem area.

O-ring

& Gasket Combination: Prevents leakage from body connection area.

Floating Spring: Loaded seats assure sealing, even at low pressures.

Metal-toMetal Sealing: When soft seals are deteriorated by fire, seat float to shut off the line media.

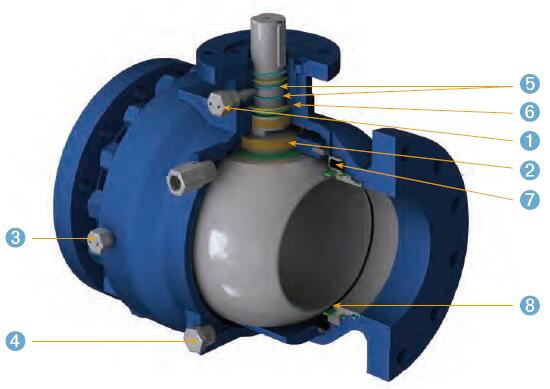

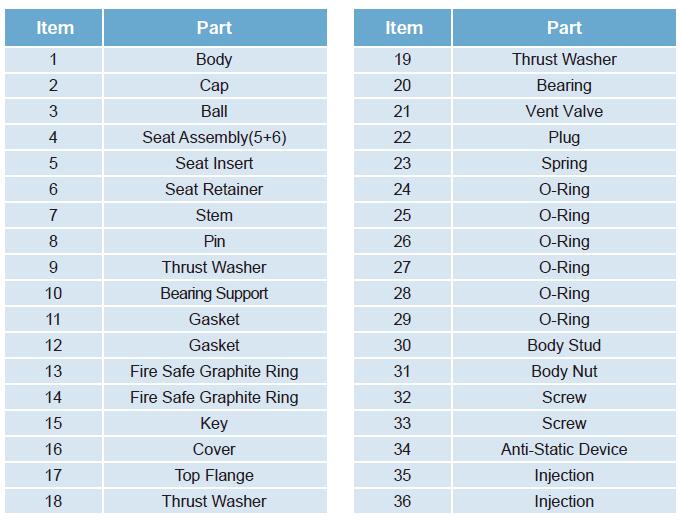

PARTS NAME OF Cast Trunnion Ball Valve

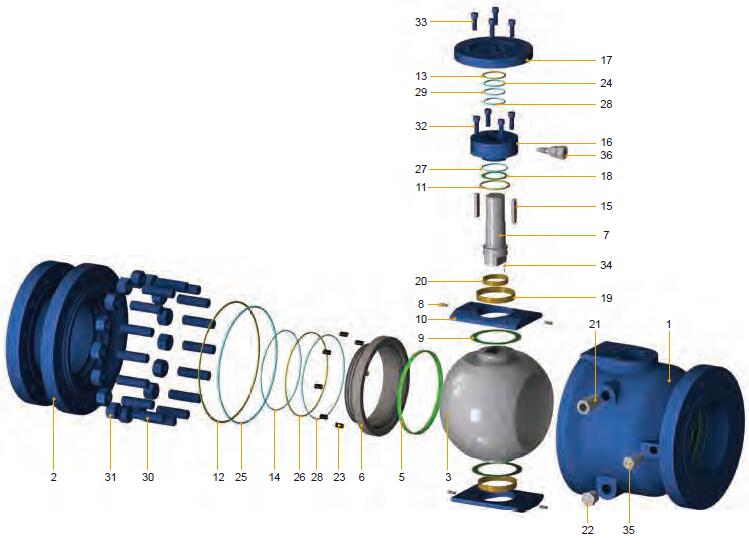

EXPLOSION VIEW OF CAST TRUNNION BALL VALVE

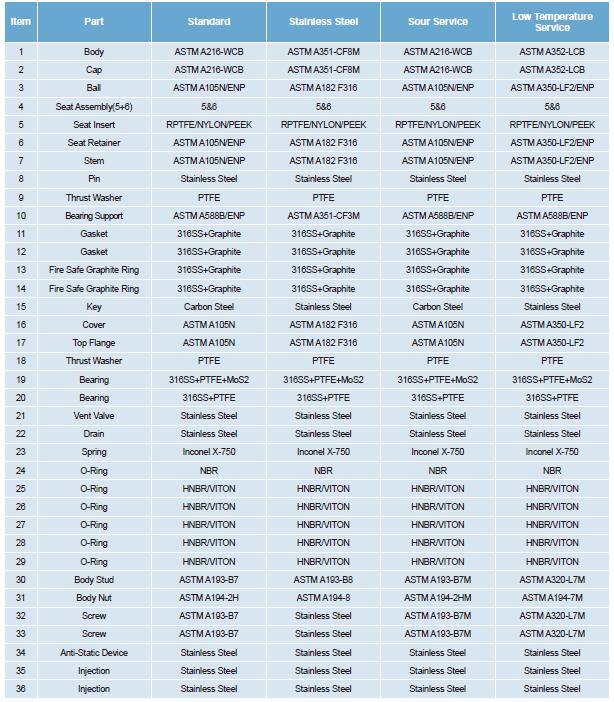

MATERIAL LIST OF CAST TRUNNION BALL VALVE