Description

Technical Specifications

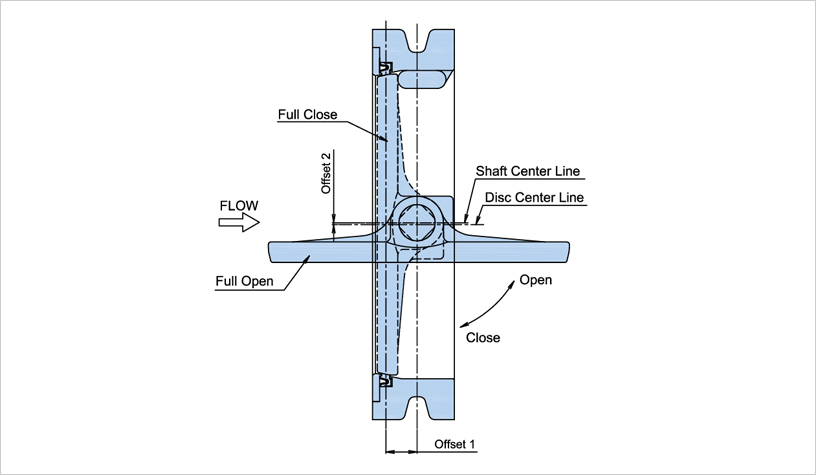

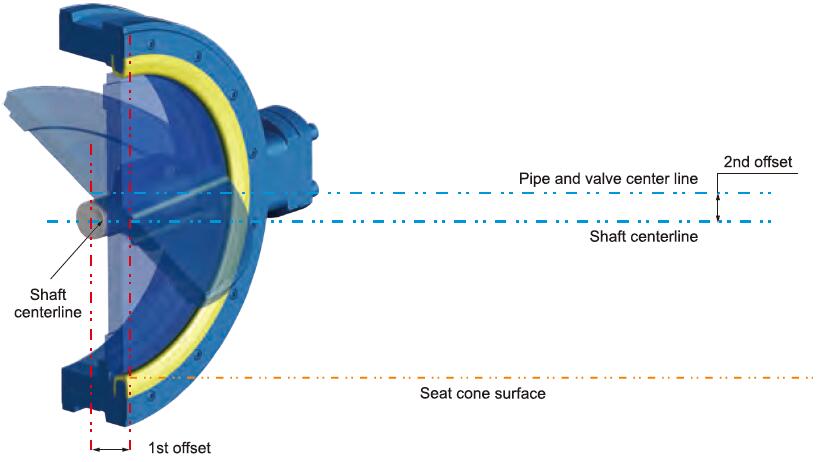

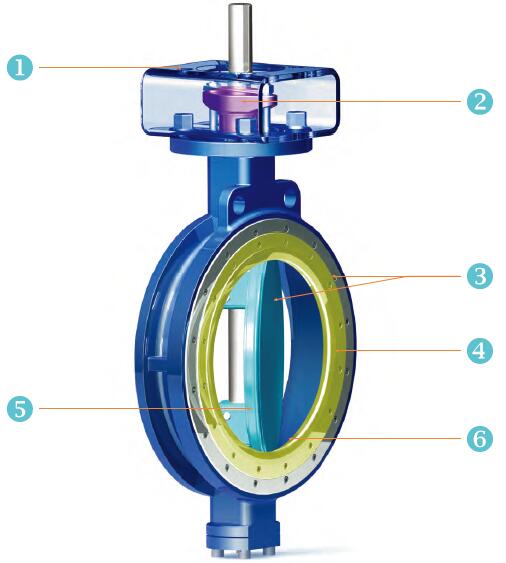

SPECS double offset Butterfly Valves or we can call them high performance Butterfly Valves, shaft offsets are created by designing the valve with the shaft located behind the centerline of the sealing surface (offset1) and slightly to one side of the pipe centerline (offset2). These double offets offer unique soft seal construction between disc and seat to get high seal performance and high durability. The seat in the body can be changed easily from the body.

Applicable Standard

Design & Manufacture Standard: API 609

Face to Face: API609, BS EN 558, DIN3202, ISO 5752

End Connection: DIN, BS, UNI, ISO, ANSI, AS, JIS

Test Standard: API598

Products Range

Size: 2" ~ 40"

Pressure Rating: 150-600LB

Body: Carbon Steel, Stainless Steel, Nickel Aluminum Bronze

Seat: NBR, EPDM, VITON, PTFE , RPTFE, Metal

End: Wafer, Lug, Flange, BW

Design Features

Double Offset Frictionless Design

1st offset: Shaft is positioned downstream

of the centerline of the seat.

2nd offset: Shaft is off center of the vertical axis of the seat.

Seat Structure

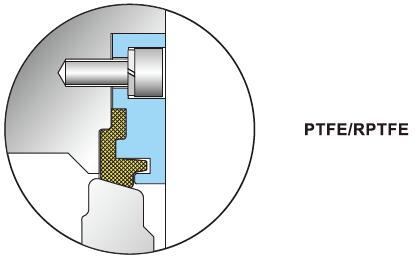

1. Double Offset PTFE Seat Butterfly Valve

A surplus between PTFE Seat and Disc ensures the seal in low pressure. The force of medium always pushes seat contacting to sealing surface and becomes more reliable in high pressure. The disc surface is a sphere design to reduce frictional force, and the valve seat can be replaced easily.

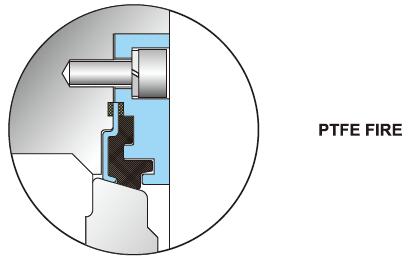

2. Double Offset Fire Safe PTFE Butterfly

Valve

Fire Safe valve Seat with dual seal including primary PTFE seat insert and metal seat. In the event that the PTFE insert is destroyed, the secondary metal seat provides effective shut-off.

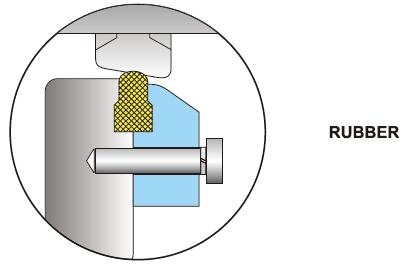

3. Double offset Rubber Seat Butterfly

Valve

A variety of rubber seat, to meet the needs of a larger size. The disc surface is designed into sphere type to reducing contacting area and frictional force which extends the usage life. Valve seat can be replaced or recharge easily.

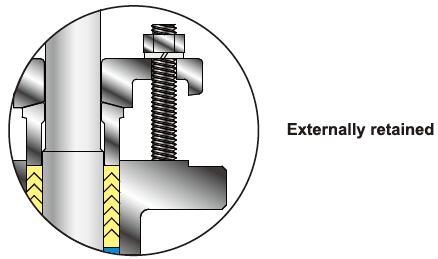

Shaft Retention

Externally retained, double blowout proof

stem design as API 609.

External: Shaft is designed with an integral collar and blowout prevented by gland follower.

Zero Leakage

Disc-Seat sealing is achieved by torque force evenly loaded on disc laminated seal edge, which has resilient function to assure Zero Leakage in both hydrostatic or air test per API 598.

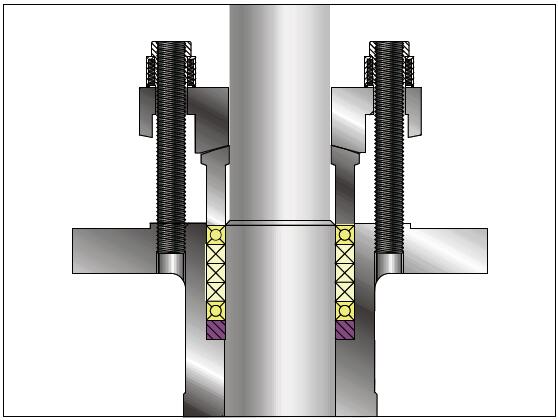

Low Emission Shaft Seal

SPECS standard emission control is 20 PPM

a.) Shaft is fully guided by shaft bearing & gland follower to avoid any side load due to line pressure thrust.

b.) The packing set is pre-compressed and is a combination of braided graphite rings top and bottom with die formed flexible graphite rings between.

c.) Controlled Ra0.4 ~ Ra0.8 finish on the shaft and Ra1.6 on the Stuffing box provides optimum packing and shaft sealing Performance.

d.) Optional Live Loaded gland flange is available to provide constant packing compression to reduce fugitive emission from shaft seal.

e.) Optional shaft seal design per Shell MESC 77/312 & TA-Luft is also available upon request.

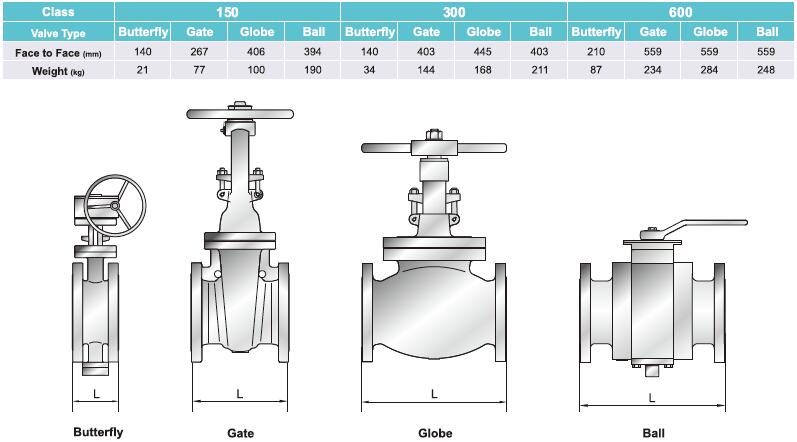

Compact & light Design

SPECS Double offset butterfly valve is designed as API 609, due to its compact & light design, it is an economical substitute for gate, globe and Ball Valves. Below is a comparison table based on a SPECS 6" valve.

1. ISO 5211 Top Flange.

2. In addition to durable, standard V-rlng

packing, you can also choose from optional, graphite high-temperature packing

or emissions control design.

3. Bi-Directional, Shut off performance.

4. Optional seat: Rubber, PTFE, RPTFE, Fire

Safe PTFE.

5. Long life durability of double offset operating principal minimize seat wear & lower operating torques.

6. Positive sealing which is mechanically achieved and does not rely on line pressure assistant.

Double offset Construction